DeCARbonising the UK

One of the most talked about topics at COP26 is the transition to electric vehicles (EVs) - and for good reason: the transport sector is one of the greatest contributors to greenhouse gas (GHG) emissions in the UK (the largest in 2019). Diving further into the domestic transport sector, cars have been found to generate the greatest proportion of GHG emissions, highlighting the need for a cleaner alternative.

As part of the UK Government’s Road to Zero strategy, the sale of all petrol and diesel cars will be phased out by 2030. With planned incentives being introduced until then, the number of EVs will rocket (an estimated 14 million EVs to be in use by 2030). With increased use comes increased need for infrastructure / charging points, which the Government is investing £620 million towards, with a further £320 million to help the automotive supply chain shift to electric.

Whilst this push for EVs is welcomed, this is not a holistic approach. The waste and carbon emissions associated with battery manufacturing and the mining of the ever-diminishing supply of critical raw materials cannot be ignored, despite the huge reduction in GHG emissions during an EV's use. The production of EVs typically uses three to four times the amount of copper found in combustion engines and overall production produces 1.4 times the emissions.[1] With road traffic in the UK set to increase by 22% until 2035[2], the focus of a more environmentally-friendly transport sector needs to on making the most of what we have, both from retaining existing material in future supply chains and from getting the most from our existing transport network.

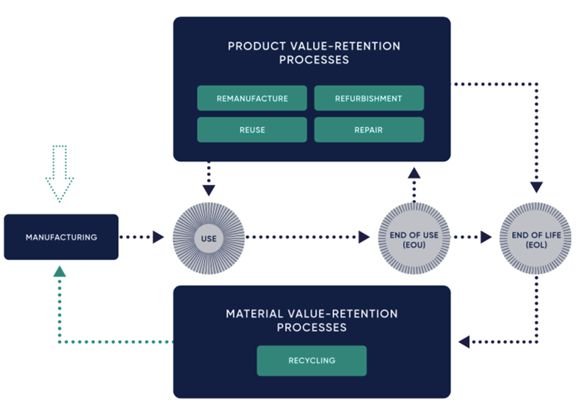

We need a national strategy that incorporates these types of circular economy principles, to get the most out of the material we extract from our Earth. The purpose of value retention is to extend the functional life of products or derive the most value out of materials. From a product perspective, this includes remanufacturing, refurbishment, reuse and repair, while material retention includes high-quality recycling (see figure below).

Although finding recycling options for end-of-life vehicles is important, product value retention is a greater priority because a significant amount of energy is saved if the material embedded in a product doesn’t need to be reprocessed. As car manufacturers move towards electrified fleets, those options that retain value and manage the existing car parc will be increasingly important. Car owners often keep a vehicle for over 10 years, so finding ways of managing the internal combustion engines in 2030 that are sold today needs to be an priority. This is where remanufacturing can have the biggest impact.

Some governments are slowly beginning to understand this potential; take, for example, a recent EU consultation on the End-Of-Life Vehicles Directive that aims to create separate targets for reusing components because reuse has a higher impact on emissions savings than recycling does. Historically the EU’s targets have been focused on recycled content; by having separate reuse targets, policy makers can facilitate a circular economy in the automotive industry. Similar strategies can be implemented in the UK, and will drive the use of reused and remanufactured components in new vehicles where traditionally these components only had a role in the aftermarket.

This comprehensive plan should look at the whole transport sector, instead of focusing on meeting future demands for private car ownerships. This can be done through demand-reduction strategies which include ways of reducing the number of vehicles on road or the number of people travelling at peak times. Examples of these strategies include current regulations like congestion and low emission zones, which deter unnecessary driving in cities. More can be done through the Government assisting with new business models and integrating both public and private transport options.

Product life extension strategies can play a large role in changing business models: take mobility-as-a-service (MaaS), for example. This concept entails users paying for private and public transport services rather than owning a car. Uptake of this type of strategy is set to be popular, with an estimated three quarters of the cars on our road not being owned by individuals by 2040.[3] Most vehicles will be managed in fleets, and using refurbished or remanufactured vehicle components can lower maintenance costs and will have a lower carbon footprint than buying new components. The changes in powertrains and business models will hopefully lead to carmakers incorporating end-of-life understanding into the vehicle design stages so that components are made with remanufacturing in mind.

Transitioning away from combustion engines to EVs will solve some - but not all - of our problems. We need to have a holistic approach to reaching net zero that involves looking at alternative powertrains, material retention, and developing business models that can help get the best out of electric vehicles coming onto the market. With the number of EVs growing, understanding how to retain and extend the life of vehicle components is essential.

To learn more about value retention speak to our consultants Rachel Waugh and Anjalee Ramjee.

References:

[1] V.M. Smith and G.A. Keoleian, The Value of Remanufactured Engines: Life-Cycle Environmental and Economic Perspective (2004) Journal of Industrial Ecology

[2] Decarbonising Transport – A Better, Greener Britain (publishing.service.gov.uk)

[3] Advanced Propulsion Centre UK, How are we powering the way to net-zero emissions? Alternative fuels, hydrogen and electricity (2021), Road to COP26: Energy