Servitization and circular economy: a case in the automotive sector

Author: Vivian Shi

Background

Context

Servitization has been closely linked to the circular economy, as a means of enabling decoupling between growth and resource use.[1] The key idea is that keeping products and materials in circulation for longer leads to less waste generation, improved utilisation of resources, and reduced demand for raw material extraction.

Servitization describes a shift away from purely product-sales-based business models by incorporating more service content into the offering. In real terms, this could be to retain the sale aspect but with more service-based content and opportunities for return, or, what is more typically associated with the term, offer access to products rather than traditional sale and transfer of ownership of products.

Models such as product leasing, renting or sharing, and pay-per-use focus on selling functionality rather than the product itself. This means that companies, instead of customers, retain the ownership of the product. If such models are adopted by OEMs, they are incentivised to optimise their designs and/or through-life services to enable product life-extension processes such as remanufacturing, repair and maintenance to take place over the product’s life. However, it may also be intermediaries – not OEMs – that take up these models. As well as achieving value from longer product lifespans, once product life-extension processes have been exhausted maximum value should be extracted from the product materials.

There is a business case for customers too who could benefit in several ways. For example, customers could better manage financial risks by replacing a high, periodic capital cost with a lower, more regular cost and avoiding unexpected replacement and/or maintenance costs. They could also benefit from predictive maintenance to support upgradability and ensured product functionality.

While not a silver bullet, servitization has shown economic and environmental success in various products and sectors. For example, for every car in a car sharing scheme like Move About, between 5 and 7 privately owned cars could be replaced, and an average member of a car sharing club drives on average about 30 per cent less than with own car.2 Moving forward, servitization models are being trialled in the transport sector motivated by technology drivers such as digitisation, political and social concerns about climate change, energy security and air quality, among other commercial drivers.[2]

As governments push towards a green recovery, more businesses should engage with circular economy, develop a new vision of what their business model could look like and take proactive steps to improve their economic and environmental outlook – in order to align better with government objectives and stay ahead of potential policy interventions. To that end, servitization is an option worth exploring especially for businesses and sectors with complex products, high environmental footprints and where there is currently a low degree of ‘circularity’ in their value chain. The question that naturally follows is: how to figure out whether servitization is going to work in practice? The ECOBULK[3] demonstration project is trying to do just this, and provides an approach to how businesses could assess the commercial viability of servitization in a pragmatic and quantitative manner. As detailed below, working with Microcab as part of ECOBULK, Oakdene Hollins modelled the whole life economics of a uniquely designed hydrogen fuel cell vehicle offered in a servitization model. We believe many of the approaches and tools we developed for the automotive sector within the ECOBULK project are transferable to other businesses and industries. While most of the work has been designed for original equipment manufacturing (OEM) companies, the approach can be adapted for a component manufacturer.

Introduction to the case

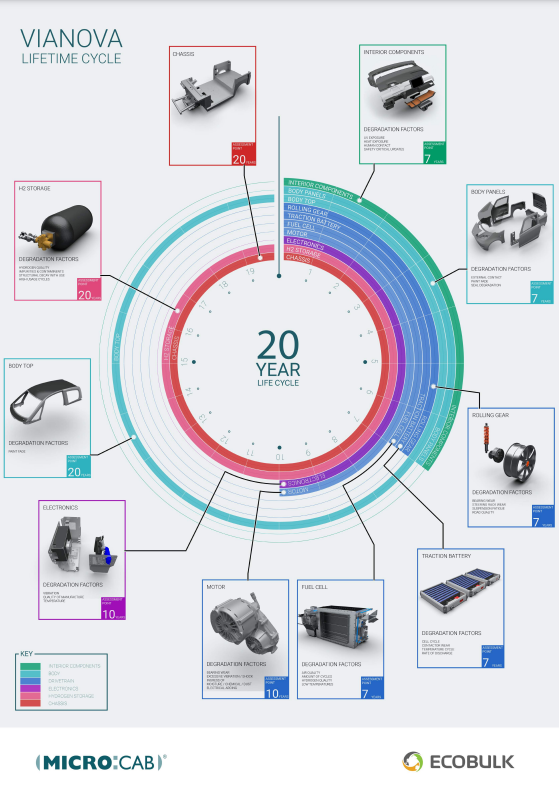

Microcab is a leading hydrogen fuel cell vehicle company based in Coventry, UK. From the outset, they recognised that different parts of a vehicle degrade at different rates depending on the design, material properties, and functions performed. This represents an opportunity for targeted maintenance, replacement and upgrade enabling the full life of the longest life component to be reached. This maximises the economic and environmental value embodied in the longer-lasting components of the product. Microcab has adopted this approach at the outset by designing a modular vehicle, so that components can be removed and replaced relatively easily. The vehicle can therefore be ‘refreshed’ throughout a 20-year lifetime without becoming functionally obsolete – this is nearly double the typical vehicle age.[4]

Source: Microcab

Microcab’s ambition is to couple their modular design and maximum value retention approach throughout the product life cycle with a mobility-as-a-service business model. Oakdene Hollins collaborated with Microcab to answer three questions central to determining the commercial viability of Micorcabs latest vehicle, the Vianova, compared to its internal combustion engine vehicle (ICEV) and battery electric vehicle (BEV) competitors with a conventional ownership-based model:

1. How much does it cost to manufacture the modular Microcab Vianova model, compared to ICEV and BEV?

2. How cost competitive is the Vianova from a consumer’s perspective? This relates to the running cost of the three types of vehicles.

3. During a 20-year period, a consumer could subscribe to Microcab’s service, or they could consecutively purchase two ICEVs or BEVs each with a 10-year functional life. Which option presents a greater cost saving for the consumer? This relates to the cost over lifetime mileage of the three types of vehicles.

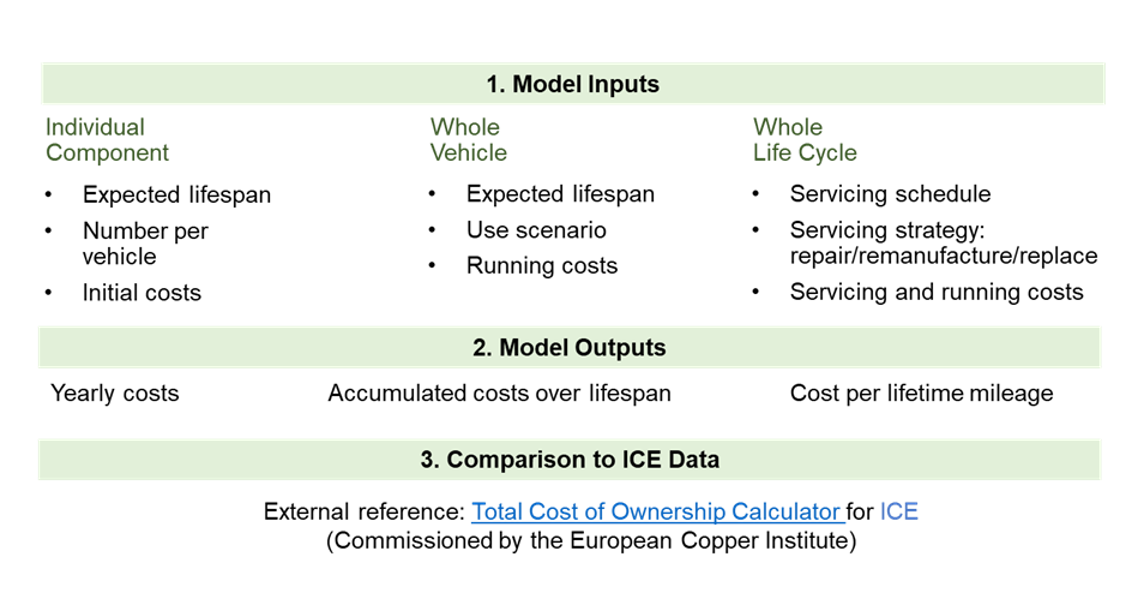

Our approach

We developed a model to quantify the life cycle cost of Vianova from the bottom up. We constructed the model to account for component characteristics, vehicle characteristics, and the whole life cycle. Component characteristics included expected lifespan of the part, number of parts present in the vehicle, suitable value retention strategy and initial costs. Vehicle characteristics included factors such as the expected lifespan, fuel efficiency, annual mileage and potential costs from driving in ultra-low emission zones. Based on these factors we modelled the schedule, type and sequence of value retention processes that would be performed on various components throughout the vehicle’s life cycle.

By modelling the costs of different types of vehicles, we were able to compare the Microcab Vianova to the Toyota AYGO (ICEV) and the Renault ZOE (BEV). Using data from the Total Cost of Ownership calculator commissioned by the European Copper Institute, we compared the three vehicles by their annual running costs, accumulated costs over lifespan, and the cost per lifetime mileage.

Our findings

It is not surprising that the current cost of manufacturing the Microcab Vianova is significantly higher than the Toyota AYGO and the Renault ZOE. This is expected to drop significantly as Microcab achieves greater production scale. On the other hand, our model tallied up the annual running costs for the Vianova including the labour and material costs required for servicing activities throughout the product life cycle. We found that the running costs for the Vianova are lower than that of ICE and BEV. This is primarily because the Vianova is subject to lower registration tax, fuel cost, and depreciation cost.

Finally, our model revealed that although the Vianova’s cost per lifetime mileage starts high due to the current manufacturing cost, this would decrease by 76% within the first 5 years of use. By doubling the lifetime, the Vianova is expected to be cost competitive against the AYGO and ZOE on the basis of cost over lifetime mileage. This validates the Vianova and the servitization model as a viable and valuable offering to their potential customers.

Outlook

The model we developed for Microcab was used to explore the high-level economics of the business model. This approach and the model itself can be expanded to further interrogate the cost and revenue streams, for example by accounting for logistic costs (e.g. delivery of parts) and potential losses in the system (e.g. part replacements earlier than expected lifespan). We can also model how the cost, revenue, and quantities of servicing activities would evolve depending on the sales/subscription volume and the need to replace components to keep up with the technology cycle in the automotive space. We can then stress test (input extreme data to find the limits of the model) the business model and find optimal timings for on-going servicing activities. The economic model can also be used to inform the cost-benefit of modular design – an approach attracting increasing attention in many sectors.

We recognise that to fully commercialise and popularise circular product designs and business models like the Microcab Vianova, businesses must work in tandem with policy makers to go one step further and address systemic challenges. To begin with, financing for circular business models such as servitization requires a new approach to account for the distributed revenue streams and changes in the normal distribution of lifetime costs of product and material value retention activities. Technological innovations in not only product design and manufacturing processes, but also data collection and sharing across the value chain are key enablers. With various drivers already in motion and many initiatives already being trialled, servitization models underpinned by life cycle thinking present an opportunity for green recovery of the transport sector.

Oakdene Hollins has extensive experience in collaborating with both the public and the private sector, as well as trade associations on implementing circular economy. If you wish to learn more about our work with Microcab for the EOCBULK project, or explore our other work on topics such as value retention, product take back, ecodesign and extended producer responsibility, please do not hesitate to reach us at Jake.Harding@oakdenehollins.com

[1] https://ec.europa.eu/docsroom/documents/16595/attachments/1/translations/en/renditions/native

[2] https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/766759/Mobilityasaservice.pdf

[3] ECOBULK aims to contribute to “closing the loop” of composite products in the automotive, furniture and building sectors. It is promoting greater re-use, upgrade, refurbishment and recycling of products, parts, and materials - along entire newly defined supply and value chains. - https://www.ecobulk.eu/

[4] https://www.smmt.co.uk/industry-topics/sustainability/average-vehicle-age/#:~:text=Furthermore%2C%20the%20average%20age%20of,the%20increased%20longevity%20of%20vehicles.